The screw cap design of this aluminum spray bottle not only integrates modern craft aesthetics and practical functions, but also demonstrates its uniqueness and significant advantages in multiple dimensions. It uses advanced CNC machine tools and precision molds to ensure that the screw cap Every component of the cover can be controlled with micron-level precision. This not only improves the fit between the bottle cap and the bottle mouth and reduces the problem of loose sealing caused by manufacturing errors, but also makes the bottle cap more smoothly rotated to open or close, making it easier for users to operate. The inside of the screw cap adopts a multi-layer sealing structure, including rubber gaskets or silicone sealing rings. These materials have good elasticity and corrosion resistance, can effectively isolate the intrusion of air, moisture and microorganisms, and provide a solid seal for the liquid in the bottle. Protective barrier.

In order to improve the user experience, the surface of screw caps is usually designed with anti-slip textures or grooves, which not only increases the friction between fingers and the cap, allowing users to easily rotate the cap in wet or greasy environments, but also improves the The overall aesthetics and feel of the product. The aluminum material itself has good corrosion resistance and lightweight properties. After special surface treatment (such as anodizing, spraying, etc.), its anti-rust ability can be enhanced to ensure that the screw cap maintains its bright appearance and stable performance during long-term use. .

In addition to the basic sealing function, the design of the screw cap also fully considers the user's usage habits and needs, such as easy opening, anti-slip properties, and the possibility of one-handed operation, which greatly improves the user's convenience and Satisfaction. In the fierce market competition, the detailed design of products often becomes one of the key factors to attract consumers. With its exquisite appearance, stable performance and environmentally friendly properties, aluminum screw caps add unique selling points to spray bottle products, helping to enhance brand image and market competitiveness.

As a recyclable resource, aluminum has a high recycling rate and has little impact on the environment. The use of aluminum screw caps not only reduces dependence on primary resources, but also reduces waste disposal costs, conforms to the concept of green and low-carbon life advocated globally, and contributes to the sustainable development of enterprises. With consumers' increasing demand for personalization, aluminum screw caps also provide a wealth of customization options, including colors, logos, and even the addition of special functions (such as child-resistant opening designs), to meet the needs of different markets and user groups. Personalized needs.

The screw cap design of this aluminum spray bottle not only reflects technological innovation and humanistic care, but also plays an important role in ensuring product quality, improving user experience, enhancing market competitiveness, and promoting sustainable development.

Web Menu

Product Search

Exit Menu

Product Categories

What are the features or advantages of the screw cap design of this aluminum spray bottle?

-

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion Bottle

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion BottleModel Number 24-410 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

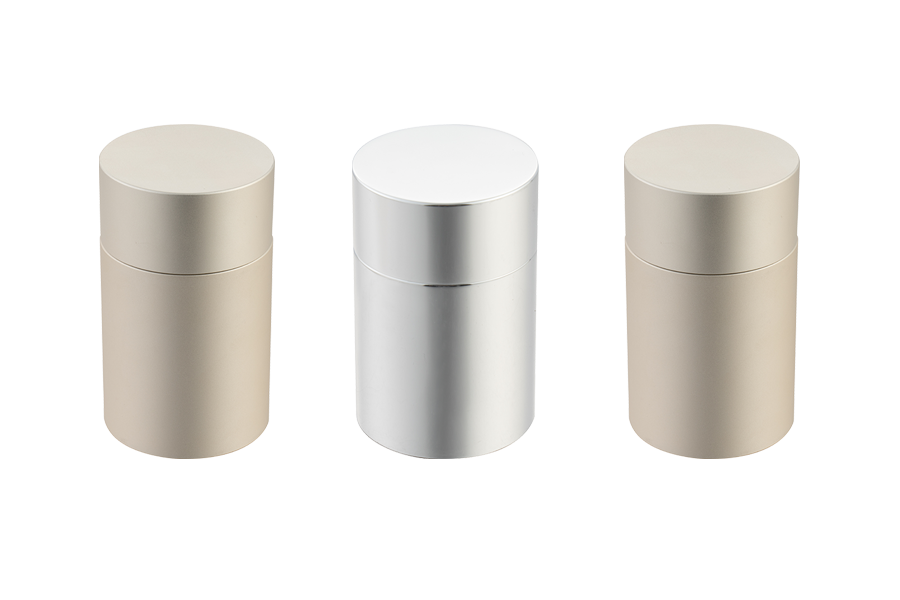

Model Number Customized Material Aluminum Usage tea caddy Custom Order: OEM or ODM Bran...

See Details -

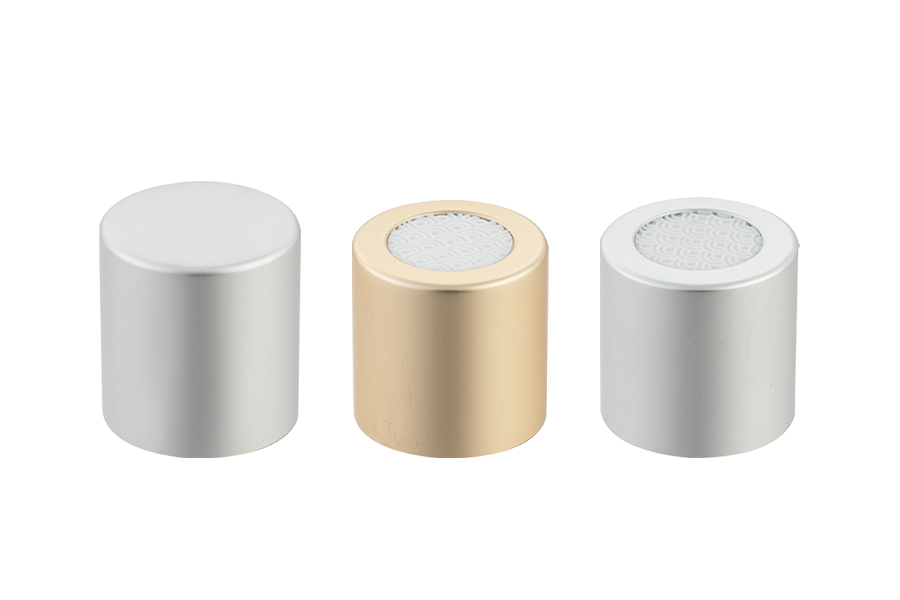

Model Number customized Material Aluminum Usage Bottles Custom Order: OEM or ODM Bran...

See Details -

Model Number 28-415 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

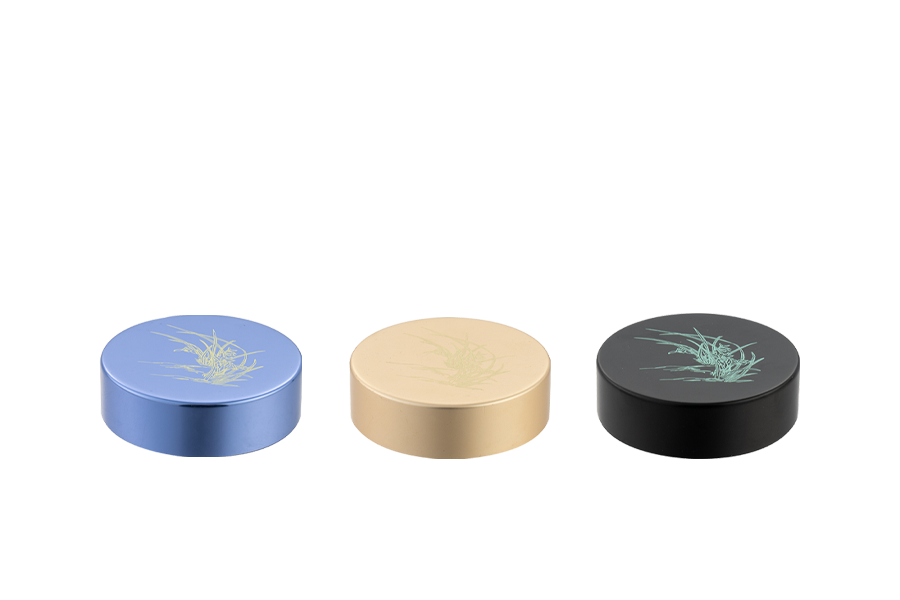

Model Number 89-400-26 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

Model Number 89-400-16 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

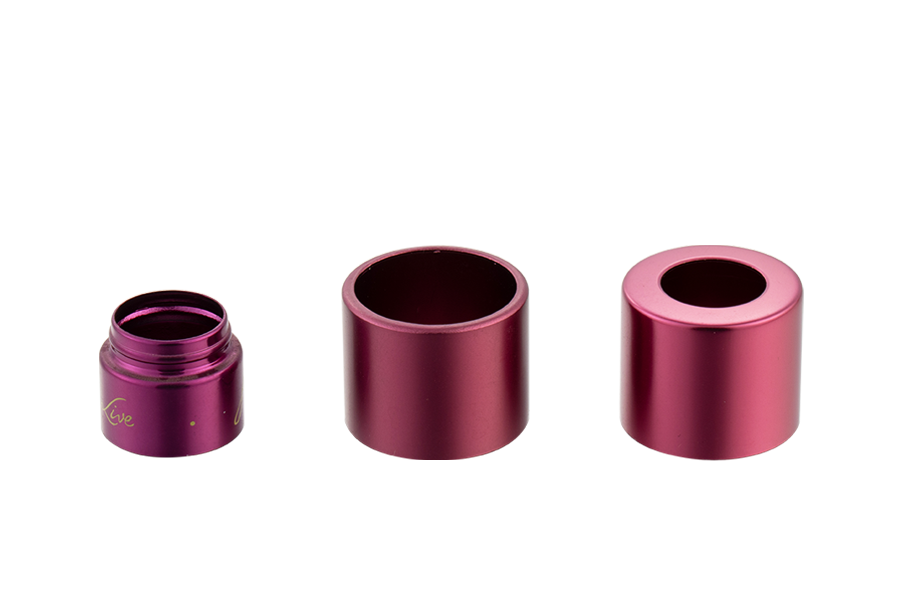

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material Aluminum-plastic Usage lotion bottle Custom Order: OEM o...

See Details -

Model Number Customized Material Aluminum-plastic Usage Cream bottle Custom Order: OEM or...

See Details

Copyright 2023 ? Zhejiang Xinbo Aluminium and Plastic Co., Ltd. All Rights Reserved. Aluminum Plastic Cosmetic Packaging Manufacturer

简体中文

简体中文 English

English