The aluminum material of the aluminum spray bottle has an extremely high recycling rate. The global aluminum recycling rate is generally high. A large number of aluminum spray bottles can be recycled and reused, reducing the need for new aluminum ore mining. The recycling and reuse of aluminum forms a closed circular economy system, which helps to reduce resource consumption and environmental pollution. Recycled aluminum can be re-melted and cast into new aluminum products. The energy consumption and greenhouse gas emissions in this process are much lower than extracting new aluminum from ore. The infinite recycling characteristics of aluminum mean that once entering the recycling system, aluminum spray bottles can be reused continuously, and the impact on the environment gradually decreases.

The recycling of plastic spray bottles faces many challenges, including a wide variety of plastics, complex recycling classification, and insufficient recycling facilities. This has led to a large number of plastic spray bottles not being effectively recycled, and eventually becoming part of landfill or marine pollution. Plastics are difficult to degrade in the natural environment. Even if they are recycled, the recycling rate of plastics is relatively low, and harmful substances may be produced during the recycling process.

Although the extraction and processing of aluminum requires a certain amount of energy, the production process of aluminum has less impact on the environment than plastic production. In particular, with the advancement of technology, the smelting and processing of aluminum has become more efficient and environmentally friendly. Many aluminum smelters have begun to use clean energy, such as hydropower, wind power, etc., which further reduces carbon emissions in the production process.

The production process of plastics requires a large amount of fossil fuels, especially oil and natural gas. This not only increases greenhouse gas emissions, but also exacerbates the energy crisis. Chemicals used in the production process of plastics may cause pollution to the environment, including water pollution and soil pollution.

Aluminum has high strength and toughness and can withstand greater pressure and impact, so aluminum spray bottles are more durable and less prone to damage. Aluminum spray bottles can withstand repeated use and cleaning, with a longer service life, reducing the amount of waste after a single use.

Plastic spray bottles have poor durability and are susceptible to wear, deformation and breakage. This results in a short service life of plastic spray bottles and requires frequent replacement. The use of disposable spray bottles is often accompanied by a lot of waste. Once used up, they are discarded and become the object of landfill or incineration.

Aluminum does not release harmful substances in the natural environment and has less pollution to soil and water bodies. Even if aluminum spray bottles are discarded in the environment, they will not cause serious damage to the ecosystem. Aluminum is a non-toxic metal and is less harmful to humans and organisms. Therefore, the use of aluminum spray bottles does not pose a potential threat to ecosystems and biodiversity.

Plastic spray bottles release tiny plastic particles during decomposition, which are called microplastics. Microplastics pose a serious threat to the environment and ecosystems. They can be ingested and accumulated in the body by organisms, causing potential harm to the health of organisms. Some plastic spray bottles may contain harmful chemicals such as BPA (bisphenol A). These substances may be released into the environment during the decomposition of plastics, causing pollution to soil and water bodies and negatively affecting the health of organisms.

Web Menu

Product Search

Exit Menu

Product Categories

What are the environmental benefits of this refillable aluminum spray bottle over a disposable spray bottle?

-

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion Bottle

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion BottleModel Number 24-410 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

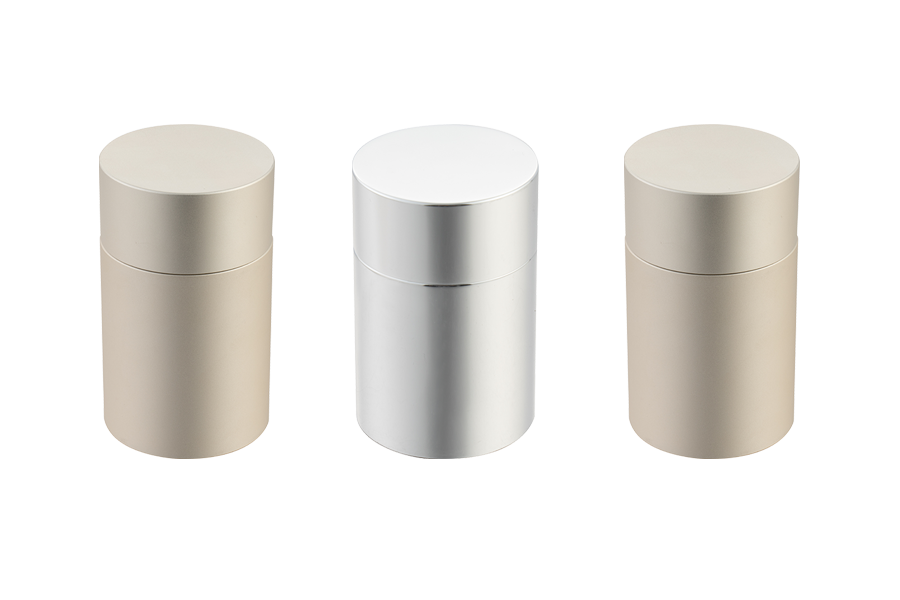

Model Number Customized Material Aluminum Usage tea caddy Custom Order: OEM or ODM Bran...

See Details -

Model Number customized Material Aluminum Usage Bottles Custom Order: OEM or ODM Bran...

See Details -

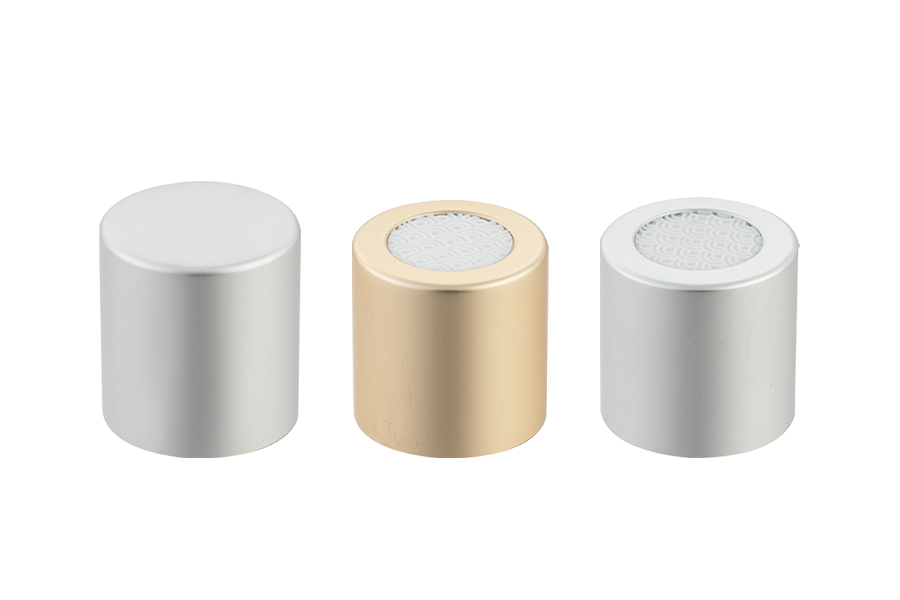

Model Number 28-415 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

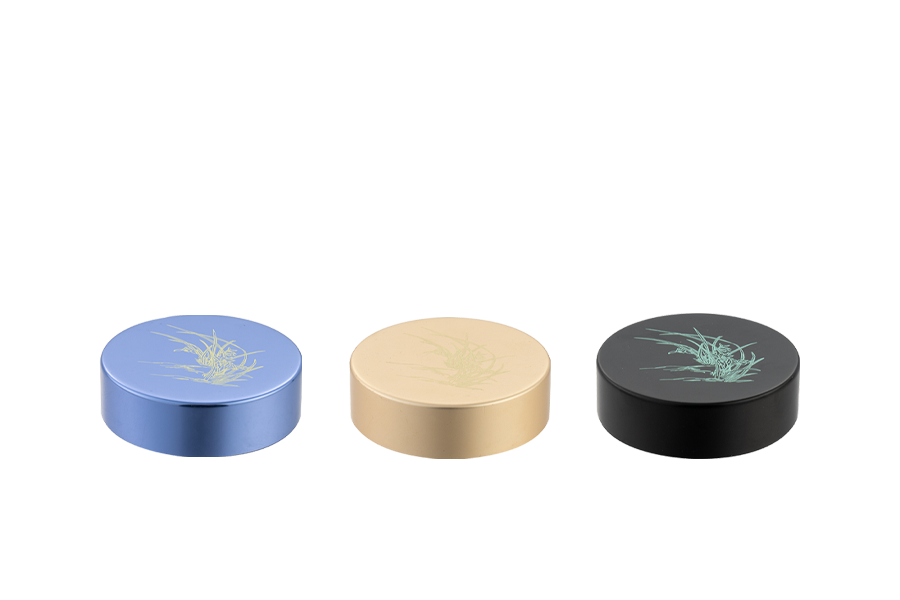

Model Number 89-400-26 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

Model Number 89-400-16 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

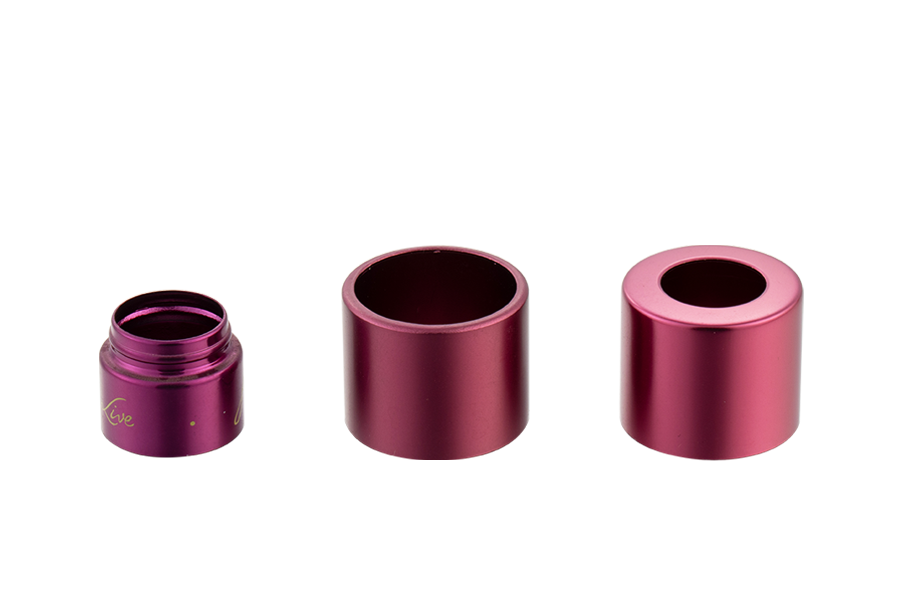

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material Aluminum-plastic Usage lotion bottle Custom Order: OEM o...

See Details -

Model Number Customized Material Aluminum-plastic Usage Cream bottle Custom Order: OEM or...

See Details

Copyright 2023 ? Zhejiang Xinbo Aluminium and Plastic Co., Ltd. All Rights Reserved. Aluminum Plastic Cosmetic Packaging Manufacturer

简体中文

简体中文 English

English