The round aluminum-plastic cream screw lid achieves a balance between lightness and corrosion resistance in terms of material, mainly due to its carefully designed composite material structure and surface treatment process. The inner cover of the aluminum-plastic cream screw lid is made of plastic, such as polypropylene (PP), polyethylene (PE) and other lightweight plastic materials. These plastic materials not only have excellent corrosion resistance and can resist the erosion of most chemicals, but also have low density and light weight, making the entire screw lid lightweight and portable while maintaining structural strength. The outer layer is covered with an aluminum oxide lid. Aluminum oxide is a metal oxide with high hardness, high wear resistance and corrosion resistance, which can effectively protect the internal plastic layer from erosion by the external environment, such as moisture, oxidation, etc. At the same time, the density of alumina is relatively low and will not significantly increase the weight of the entire screw lid.

By using a composite structure of inner plastic and outer alumina, the product not only takes advantage of the lightweight corrosion resistance of plastic, but also takes advantage of the high hardness and wear resistance of alumina, achieving complementary material properties. In terms of structural design, through accurate calculation and optimization of the wall thickness of each part of the screw lid, sufficient structural strength is ensured, unnecessary material waste is avoided, and the overall weight is further reduced.

The surface of the aluminum cover undergoes a special oxidation treatment process to form a dense oxide film. This oxide film not only improves the corrosion resistance of the aluminum lid, but also enhances its hardness and wear resistance, making the screw lid less susceptible to damage during long-term use. On the basis of oxidation treatment, surface treatment processes such as coloring and spraying can also be carried out to make the surface of the aluminum cover beautiful and diverse, meeting customers' needs for product appearance.

The round aluminum-plastic cream screw lid successfully achieves a balance between lightness and corrosion resistance by carefully selecting lightweight corrosion-resistant plastic materials and corrosion-resistant and wear-resistant aluminum oxide materials, and adopting composite structure design and surface treatment technology. This design not only improves the performance of the product, but also meets the needs of the modern packaging industry for lightweight, environmental protection and aesthetics.

Web Menu

Product Search

Exit Menu

Product Categories

How to achieve a balance between lightness and corrosion resistance in the material of round aluminum-plastic cream screw lid?

-

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion Bottle

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion BottleModel Number 24-410 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

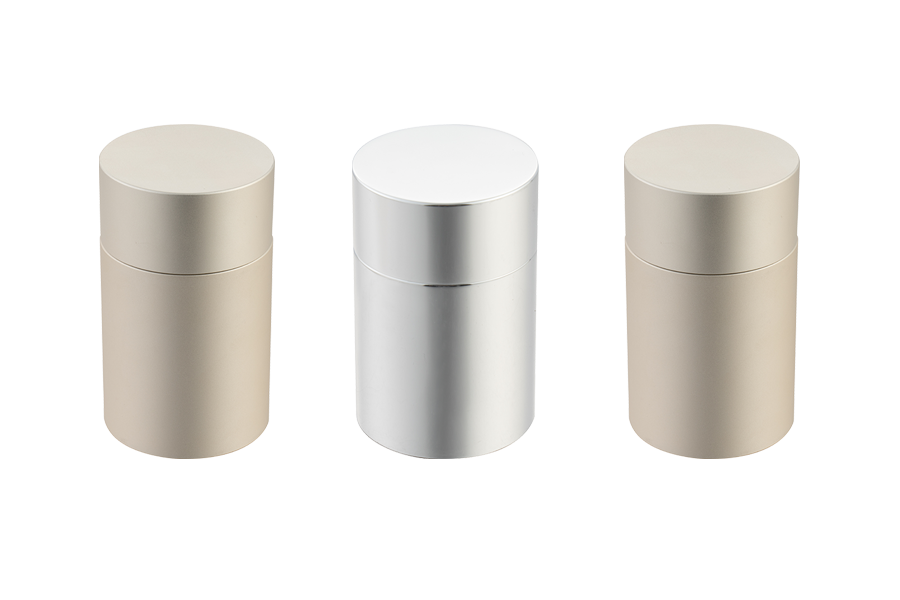

Model Number Customized Material Aluminum Usage tea caddy Custom Order: OEM or ODM Bran...

See Details -

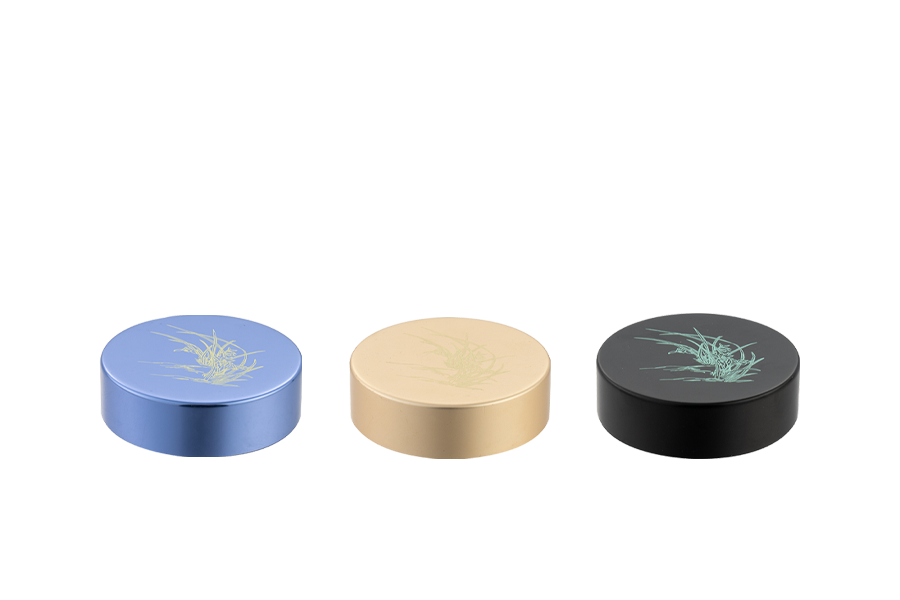

Model Number customized Material Aluminum Usage Bottles Custom Order: OEM or ODM Bran...

See Details -

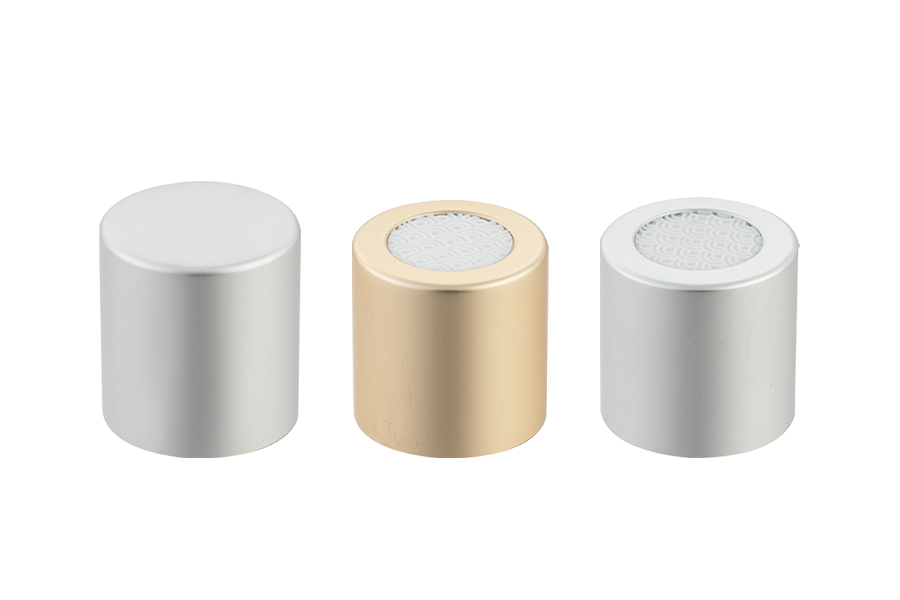

Model Number 28-415 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

Model Number 89-400-26 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

Model Number 89-400-16 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

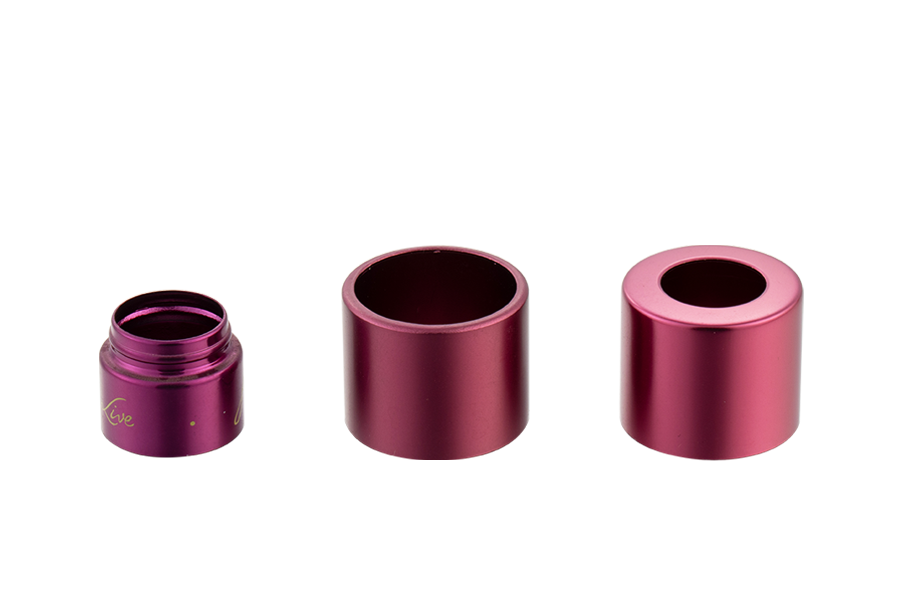

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material Aluminum-plastic Usage lotion bottle Custom Order: OEM o...

See Details -

Model Number Customized Material Aluminum-plastic Usage Cream bottle Custom Order: OEM or...

See Details

Copyright 2023 ? Zhejiang Xinbo Aluminium and Plastic Co., Ltd. All Rights Reserved. Aluminum Plastic Cosmetic Packaging Manufacturer

简体中文

简体中文 English

English