The core advantage of the Advanced Sealing Vacuum Press Bottle Aluminum Lotion Bottle is its superior vacuum sealing technology. This technology uses a precise sealing structure to create a near-vacuum environment inside the bottle, effectively blocking the intrusion of air, moisture and external pollutants. This sealing is especially important for highly viscous or low-flow emulsions, which are more susceptible to oxidation, deterioration, or contamination. The vacuum environment can significantly extend the shelf life of the lotion, maintain its original texture and active ingredients, and ensure that consumers get the best product experience when using it.

In view of the special properties of high-viscosity or low-flow emulsions, the pressing design of the High Grade Sealed Vacuum Press Bottle Aluminum Lotion Bottle has also been carefully optimized. The pump head is made of high-quality materials with excellent wear resistance and corrosion resistance, and can easily cope with changes in the viscosity of the lotion. At the same time, the internal structure of the pump head has been precisely calculated and adjusted to ensure that the lotion can flow out smoothly when pressed, and the flow rate is stable and controllable. This design not only avoids the problem of lotion remaining in the bottle or clogging the pump head, but also improves the convenience and comfort of use.

As the main material of this lotion bottle, the aluminum bottle body has significant advantages such as light weight, high strength, and corrosion resistance. It resists the attack of many chemicals, including active ingredients and preservatives in lotions, thereby maintaining the purity and stability of lotions. The inner cover is made of food-grade plastic material, which has good sealing and chemical resistance, and is perfectly compatible with high-viscosity or low-flow emulsions. The outer cover is made of aluminum oxide, which is not only beautiful and elegant, but also has excellent heat resistance and wear resistance, further improving the overall quality and service life of the product.

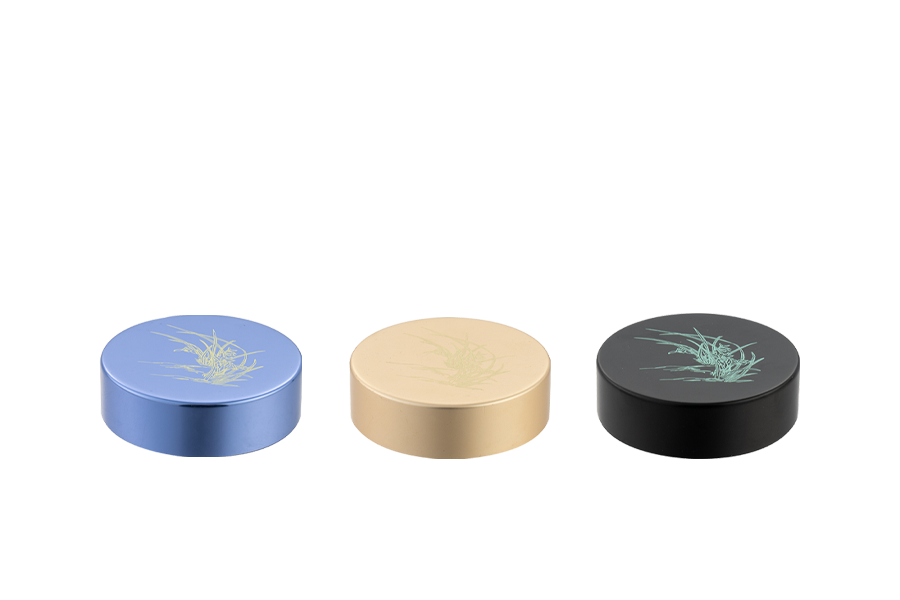

Premium Sealed Vacuum Press Bottle Aluminum Lotion Bottles also provide a wealth of personalized design options to meet the needs of different brands and products. Customers can choose suitable design elements such as colors, marks, patterns, etc. based on their own brand characteristics and market needs. This flexibility not only improves product recognition and novelty, but also enhances the brand's market competitiveness. At the same time, personalized design also provides consumers with more choices and satisfies their pursuit of personalized and differentiated products.

Today, with the increasing awareness of environmental protection, high-grade sealed vacuum push bottle aluminum lotion bottles also actively respond to the call for green development. It is made of recyclable aluminum material, reducing environmental pollution and waste of resources. After using the product, consumers can send the empty bottles to the recycling station for recycling and reuse, thus contributing to environmental protection. This environmental protection concept not only conforms to the current social development trend, but also reflects the company's responsibility and pursuit of social responsibility.

Premium Sealed Vacuum Press Bottle Aluminum Lotion Bottles demonstrate superior performance when packaging high viscosity or low flow lotions. Its vacuum sealing technology, optimized pressing design, excellent material properties, personalized design options and environmental protection concepts together constitute the core competitiveness of this product, providing high-quality packaging solutions for emulsion products.

Web Menu

Product Search

Exit Menu

Product Categories

How does the High Grade Sealed Vacuum Press Bottle Aluminum Lotion Bottle perform when packaging high viscosity or low flow lotions?

-

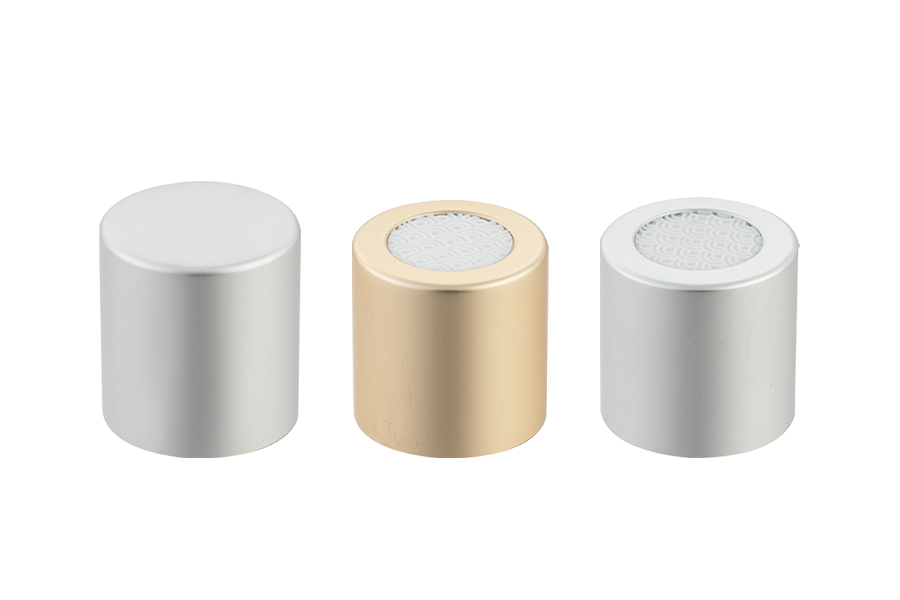

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion Bottle

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion BottleModel Number 24-410 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

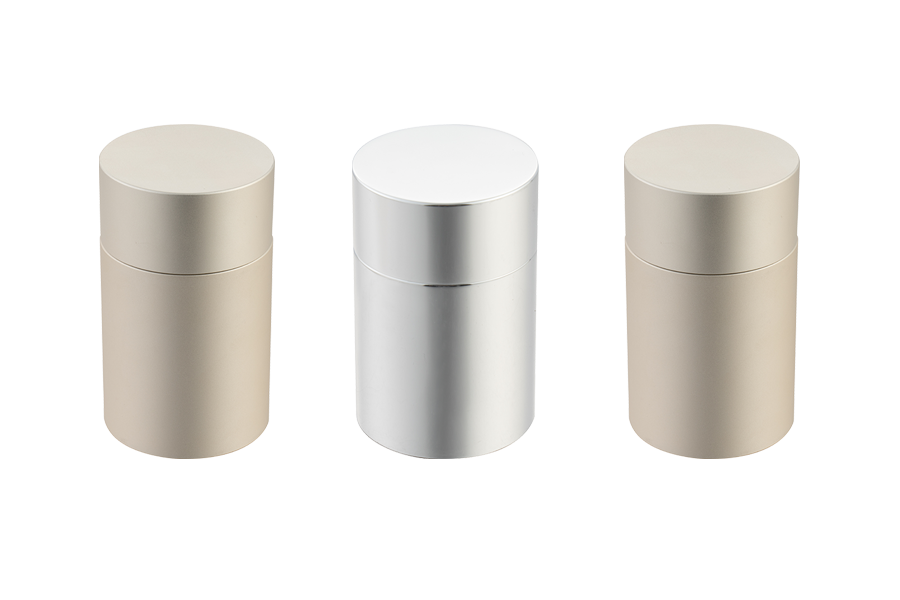

Model Number Customized Material Aluminum Usage tea caddy Custom Order: OEM or ODM Bran...

See Details -

Model Number customized Material Aluminum Usage Bottles Custom Order: OEM or ODM Bran...

See Details -

Model Number 28-415 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

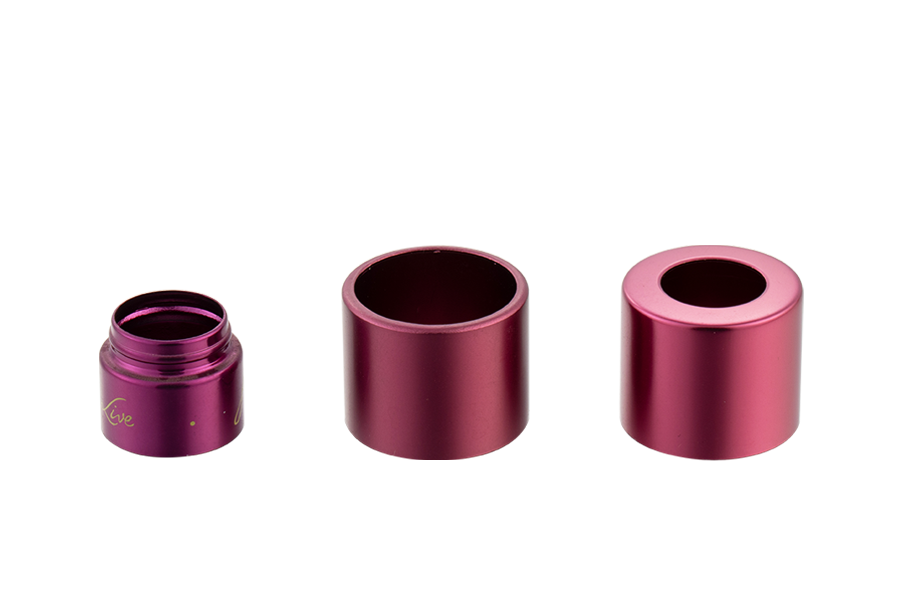

Model Number 89-400-26 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

Model Number 89-400-16 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material Aluminum-plastic Usage lotion bottle Custom Order: OEM o...

See Details -

Model Number Customized Material Aluminum-plastic Usage Cream bottle Custom Order: OEM or...

See Details

Copyright 2023 ? Zhejiang Xinbo Aluminium and Plastic Co., Ltd. All Rights Reserved. Aluminum Plastic Cosmetic Packaging Manufacturer

简体中文

简体中文 English

English