The aluminum-plastic material of this Round Thread Aluminum Face Cream Sub Bottled Ointment Bottle is generally considered safe and harmless. Aluminum is a low-toxic metal. Under normal use conditions, the aluminum ions in the aluminum container The migration level is extremely low, far below the allowable content of aluminum ions in food and drinking water. Therefore, aluminum packaging materials will not have a significant impact on human health when they come into contact with cosmetics. A dense oxide film is easily formed on the surface of the aluminum material. This film can effectively isolate moisture and oxygen from the outside world and prevent the contents from being oxidized, thereby ensuring the quality and stability of the product. Aluminum has good ductility and processing properties, and can be made into packaging containers of various shapes and specifications to meet different usage needs.

The plastic parts used in cosmetic packaging, especially those in direct contact with the contents, must be made of materials that meet food-grade standards. This type of material has undergone rigorous scientific testing and certification procedures, including toxicity testing, migration testing, etc., to ensure that it will not release chemicals harmful to the human body during long-term contact with cosmetics. Common food-grade plastics include polyethylene (PE), polypropylene (PP), polyester (PET), etc., all of which have good chemical stability and biocompatibility.

During the production process of plastics, in order to improve its processing performance, improve stability or impart specific functions, a small amount of additives, such as stabilizers, plasticizers, antioxidants, etc., may be added. However, the use of these additives must be strictly limited to ensure that their migration does not exceed safe thresholds and thus avoid potential harm to human health. Manufacturers need to follow relevant international and domestic regulations, accurately control the type, dosage and migration of additives, and ensure product safety through regular testing and evaluation.

The combination of plastic and aluminum makes full use of the flexibility of plastic and the barrier properties of aluminum, forming a composite material with complementary advantages. This composite material can provide excellent sealing performance and effectively prevent cosmetics from being contaminated by oxygen, moisture, microorganisms and other external factors during storage and transportation, thereby maintaining product quality and stability. Especially for cosmetics that need to be stored for a long time or are volatile, aluminum-plastic composite packaging is important.

As cosmetic packaging materials, aluminum-plastic composite materials must strictly comply with relevant national and international safety standards and regulations. These standards cover many aspects such as material composition, performance, migration capacity, and microbial limits, providing comprehensive protection for product safety. Manufacturers need to pass testing and certification by authoritative organizations to ensure that products meet standard requirements, and regularly conduct self-inspections and improvements on production lines to ensure continued and stable product quality.

Choosing cosmetic packaging products from well-known brands is one of the important ways for consumers to ensure the safety of materials. Well-known brands usually have more complete quality management systems and stricter raw material procurement standards to ensure that every aspect of the product from design to production meets safety standards. In addition, well-known brands also pay attention to feedback from consumers on health and product quality, and can adjust and optimize product formulas and production processes in a timely manner to meet market demand and consumer expectations.

Web Menu

Product Search

Exit Menu

Product Categories

Recent Posts

Is the aluminum-plastic material of this Round Thread Aluminum Face Cream Sub Bottled Ointment Bottle safe and harmless?

-

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion Bottle

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion BottleModel Number 24-410 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

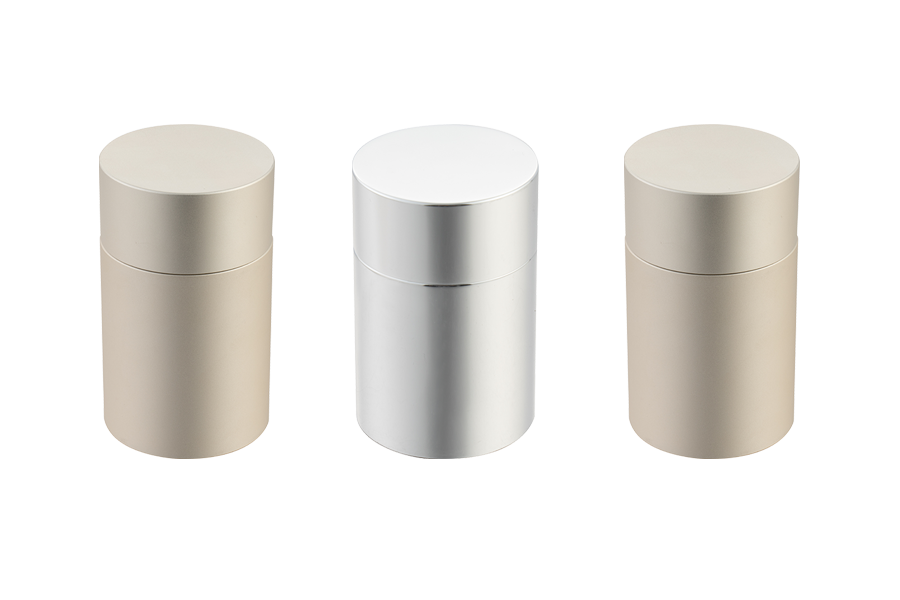

Model Number Customized Material Aluminum Usage tea caddy Custom Order: OEM or ODM Bran...

See Details -

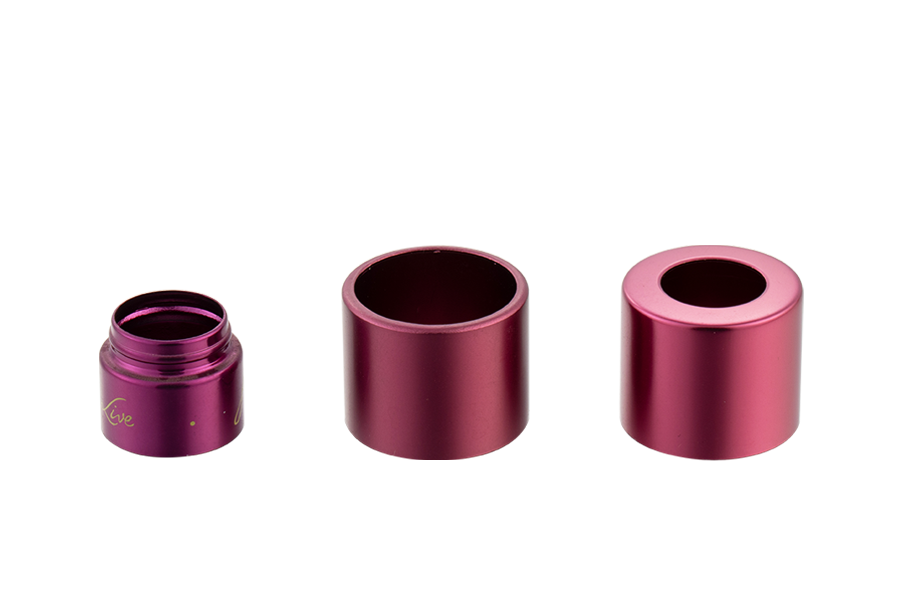

Model Number customized Material Aluminum Usage Bottles Custom Order: OEM or ODM Bran...

See Details -

Model Number 28-415 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

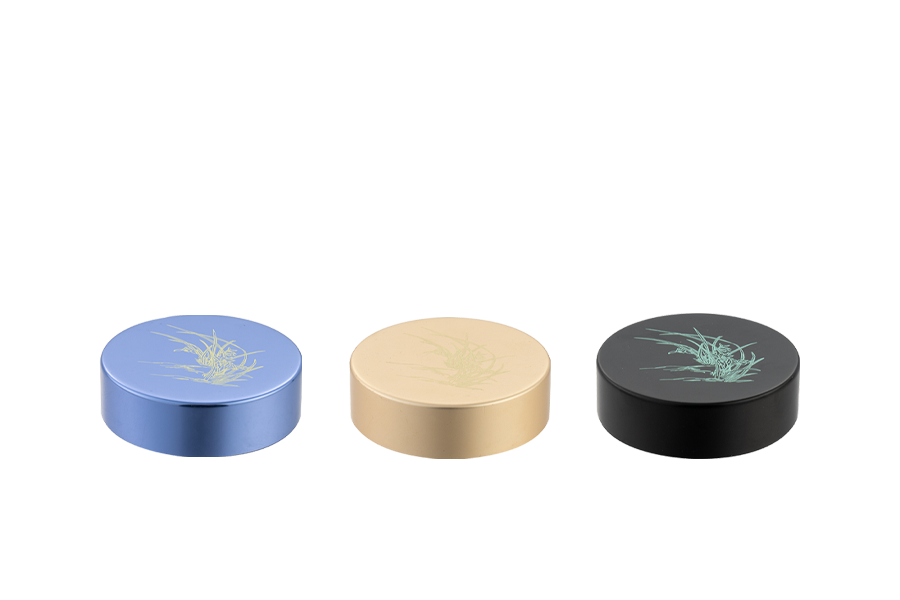

Model Number 89-400-26 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

Model Number 89-400-16 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

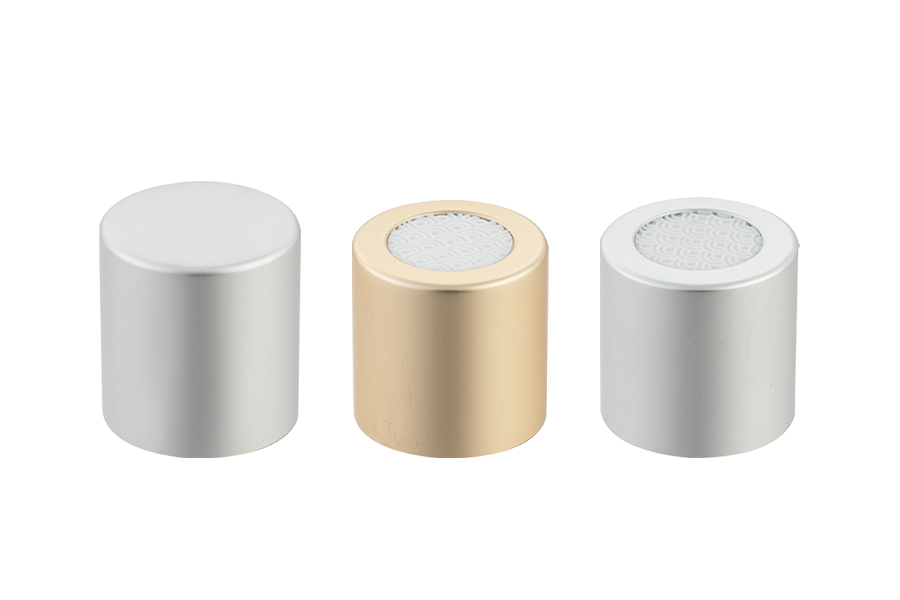

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material Aluminum-plastic Usage lotion bottle Custom Order: OEM o...

See Details -

Model Number Customized Material Aluminum-plastic Usage Cream bottle Custom Order: OEM or...

See Details

Copyright 2023 ? Zhejiang Xinbo Aluminium and Plastic Co., Ltd. All Rights Reserved. Aluminum Plastic Cosmetic Packaging Manufacturer

简体中文

简体中文 English

English