Aluminum is a very stable metal that does not react with water, gas and most chemicals. This allows Aluminum Cream Jar to effectively isolate moisture, oxygen and other pollutants in the external environment, reducing the risk of cosmetics oxidation and deterioration. Aluminum materials have a high density and a smooth surface, which can effectively block the transmission of gas and humidity. This barrier property can reduce the evaporation of moisture in cosmetics and avoid the concentration or drying of products, thereby maintaining the texture and performance of the products. Aluminum materials can block the penetration of ultraviolet rays, reduce the exposure of sunlight to cosmetics, and reduce the risk of degradation of photosensitive ingredients.

The aluminum-plastic cover that Aluminum Cream Jar are usually equipped with is an important part of ensuring the sealing of cosmetics. This cover can fit tightly on the cosmetic container through precise design and manufacturing, forming an effective barrier to prevent the entry of external air, dust and bacteria. The sealing performance of the aluminum-plastic cover is mainly reflected in its material and structure. In terms of material, aluminum-plastic materials have good elasticity and corrosion resistance, and can maintain their shape and sealing performance for a long time; in terms of structure, aluminum-plastic caps usually adopt threaded structures or snap-on designs to ensure a tight connection between the cap and the container. In addition, some aluminum-plastic caps are also equipped with sealing gaskets to further enhance their sealing effect.

In order to prevent the leakage of cosmetics during transportation and storage, aluminum-plastic caps usually have anti-leakage designs. These designs include the tight fit of threaded structures, the elastic sealing of sealing gaskets, etc., to ensure that cosmetics will not leak when subjected to external force shock or vibration. This design not only avoids waste and confusion, but also ensures that the cosmetics still maintain their original quality and performance when they reach the hands of consumers.

In the process of manufacturing Aluminum Cream Jar, it is crucial to maintain a sterile and clean environment. This helps prevent bacteria and other contaminants from entering the product during the manufacturing process, thereby maintaining the freshness and purity of the cosmetics. To achieve this goal, manufacturers will take a series of measures, such as regular cleaning and disinfection of production equipment, and the use of sterile raw materials and packaging materials.

In addition to basic sealing and anti-leakage functions, the design of Aluminum Cream Jar can also incorporate personalized elements and intelligent technologies. Personalized design is mainly reflected in the appearance. Brands can customize the unique appearance and pattern of Aluminum Cream Jar according to the preferences and needs of the target consumer groups to enhance the brand image and attract consumers' attention.

Web Menu

Product Search

Exit Menu

Product Categories

How can the design of Aluminum Cream Jar effectively protect cosmetics from external air, moisture, light and bacteria?

-

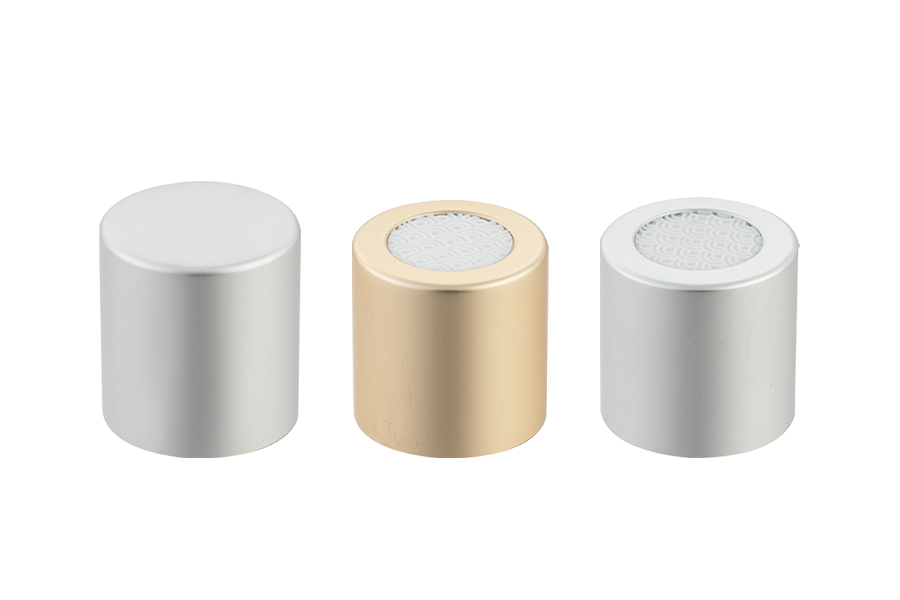

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion Bottle

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion BottleModel Number 24-410 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

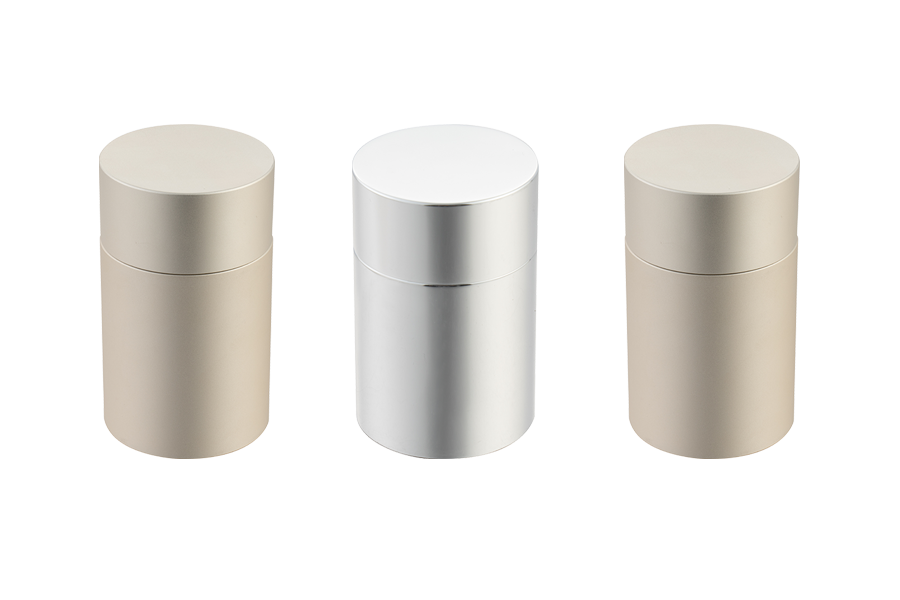

Model Number Customized Material Aluminum Usage tea caddy Custom Order: OEM or ODM Bran...

See Details -

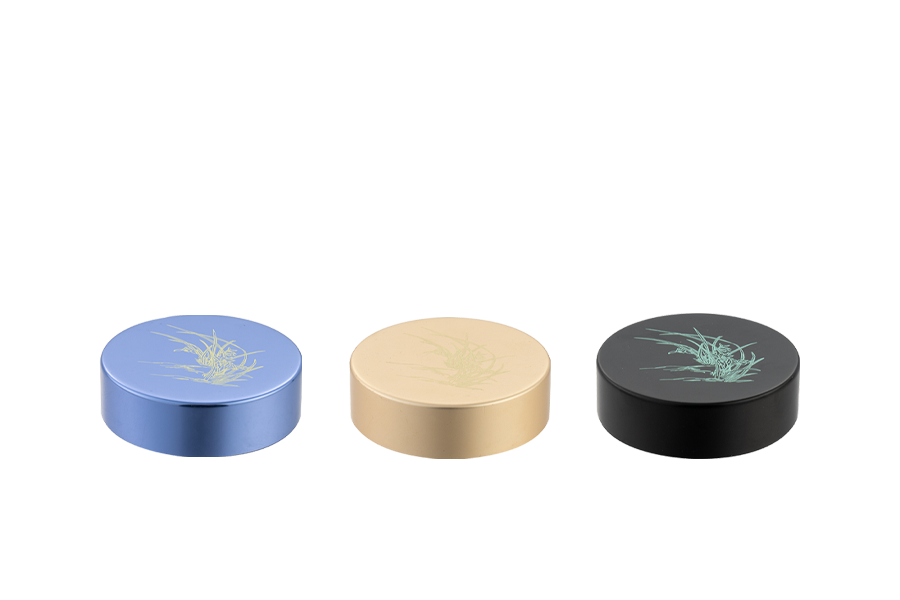

Model Number customized Material Aluminum Usage Bottles Custom Order: OEM or ODM Bran...

See Details -

Model Number 28-415 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

Model Number 89-400-26 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

Model Number 89-400-16 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

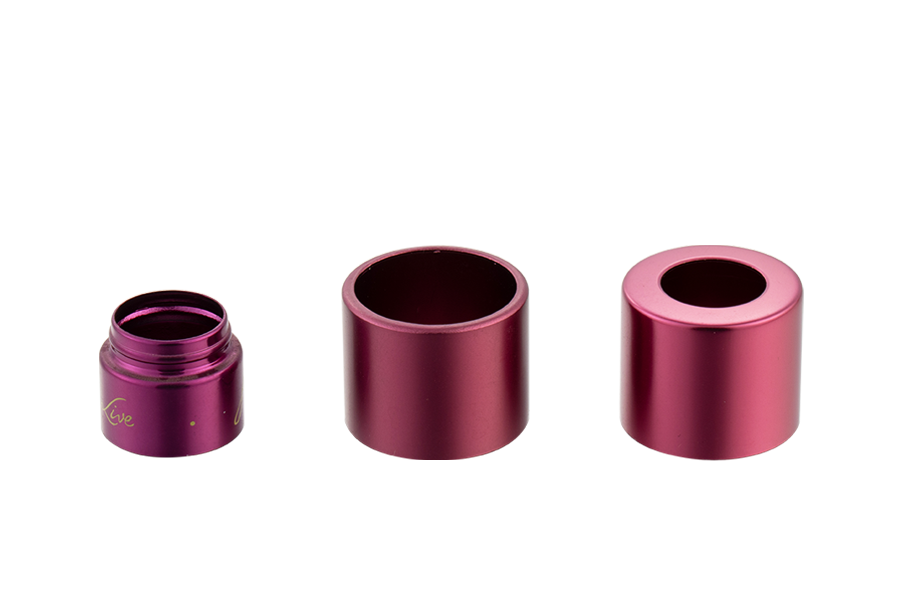

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material Aluminum-plastic Usage lotion bottle Custom Order: OEM o...

See Details -

Model Number Customized Material Aluminum-plastic Usage Cream bottle Custom Order: OEM or...

See Details

Copyright 2023 ? Zhejiang Xinbo Aluminium and Plastic Co., Ltd. All Rights Reserved. Aluminum Plastic Cosmetic Packaging Manufacturer

简体中文

简体中文 English

English