The manufacturing process of the Cosmetic Set Accessories Aluminum Middle Ring meets environmental protection standards to a large extent. However, due to the differences in the actual conditions and technical levels of different manufacturers, consumers should pay attention to factors such as the manufacturer's environmental certification, production process, and the quality and safety performance of the product itself when choosing products.

In the early stage of the manufacturing of aluminum middle rings, the selection of raw materials is crucial. Modern manufacturers tend to use high-purity recycled aluminum or strictly screened primary aluminum as the main material. Recycled aluminum is made by recycling scrap aluminum products for reprocessing. This process not only reduces the mining of primary mineral resources, but also reduces energy consumption and greenhouse gas emissions in the production process. At the same time, high-purity aluminum materials ensure the quality and durability of the products, and reduce early elimination and resource waste caused by product quality problems.

Manufacturers optimize the production process and reduce energy consumption by adopting advanced smelting and casting technologies. For example, the use of efficient and energy-saving smelting furnaces and casting machines, as well as automated production lines, can significantly reduce energy consumption and carbon emissions.

During the production process, manufacturers strictly control the emission of waste gas, wastewater and solid waste. By installing efficient waste gas treatment equipment, such as desulfurization, denitrification and dust removal devices, ensure that waste gas emissions meet national and local environmental protection standards. Wastewater is treated before discharge to remove harmful substances. Solid waste is sorted and recycled to maximize resource utilization. In addition, manufacturers will take measures to reduce noise and vibration during the production process to protect the surrounding environment and the health of employees.

In the customization process of aluminum central rings, especially the printing of colors and logos, manufacturers will choose environmentally friendly coatings and printing technologies. These coatings usually have low VOC (volatile organic compound) content and have less impact on human health and the environment. At the same time, the use of water-based printing technology or other environmentally friendly printing methods can reduce pollution to the environment.

In order to prove the environmental friendliness of their products, manufacturers usually actively seek and obtain relevant environmental certifications. These certifications include but are not limited to ISO 14001 environmental management system certification, RoHS (Restriction of the Use of Certain Hazardous Substances) compliance certification, etc. These certifications not only prove that the company pays attention to environmental protection during the production process, but also indicate that its products meet international environmental standards and regulatory requirements.

As responsible corporate citizens, manufacturers will continue to pay attention to the development of environmental protection technologies and the updating of industry standards, and constantly improve their own production processes and environmental protection measures. At the same time, they will actively participate in social welfare activities, advocate green consumption and environmental protection concepts, and contribute to the promotion of sustainable development.

Web Menu

Product Search

Exit Menu

Product Categories

Recent Posts

Does the manufacturing process of the Cosmetic Set Accessories Aluminum Middle Ring meet environmental protection standards?

-

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion Bottle

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion BottleModel Number 24-410 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

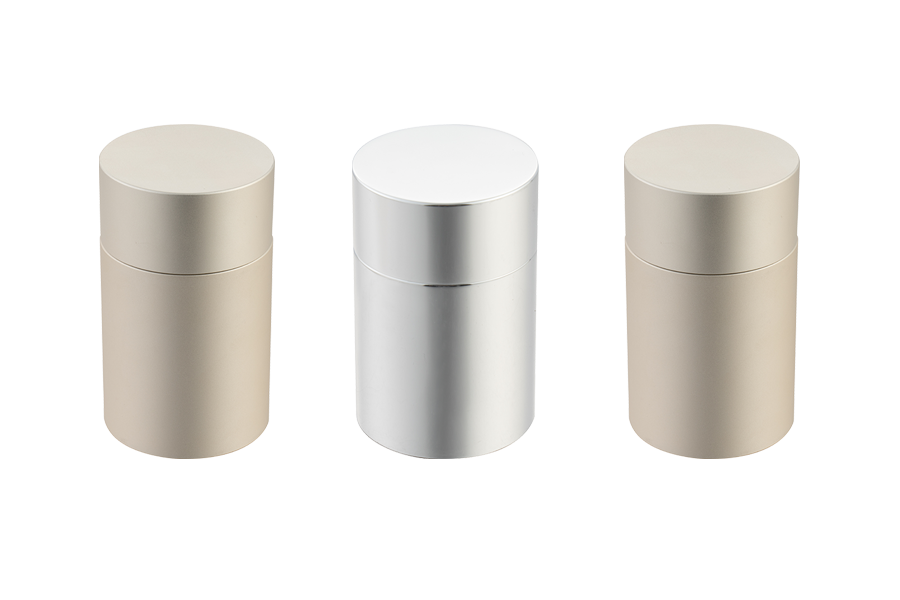

Model Number Customized Material Aluminum Usage tea caddy Custom Order: OEM or ODM Bran...

See Details -

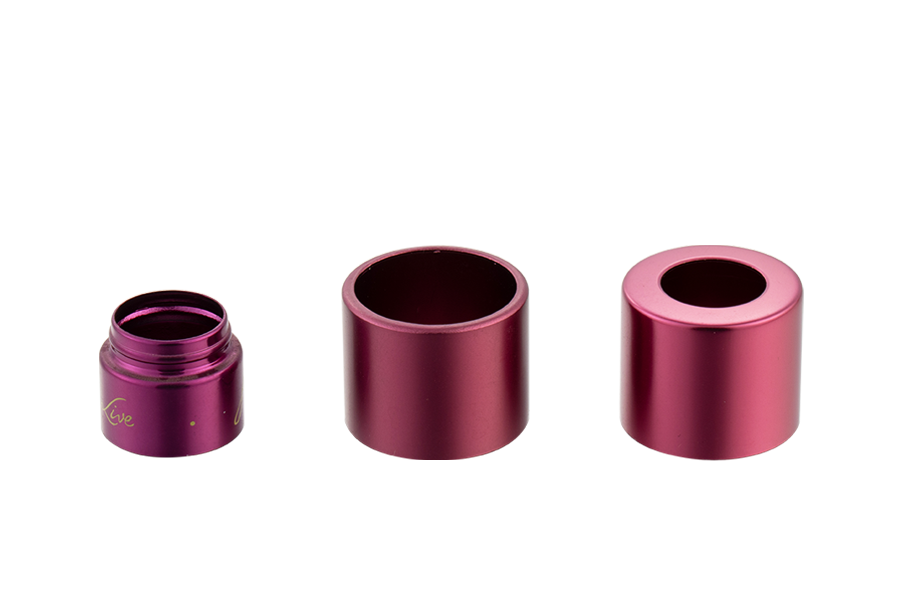

Model Number customized Material Aluminum Usage Bottles Custom Order: OEM or ODM Bran...

See Details -

Model Number 28-415 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

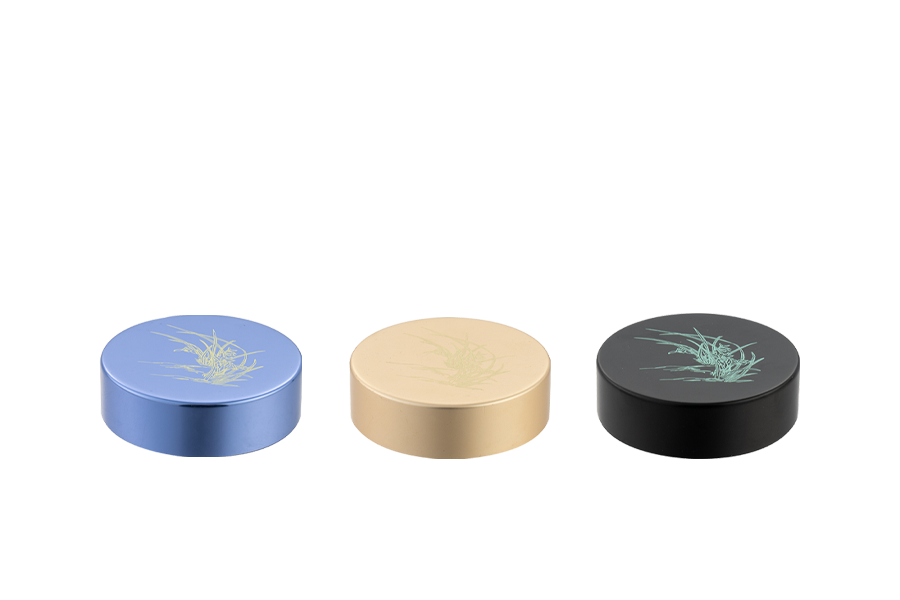

Model Number 89-400-26 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

Model Number 89-400-16 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

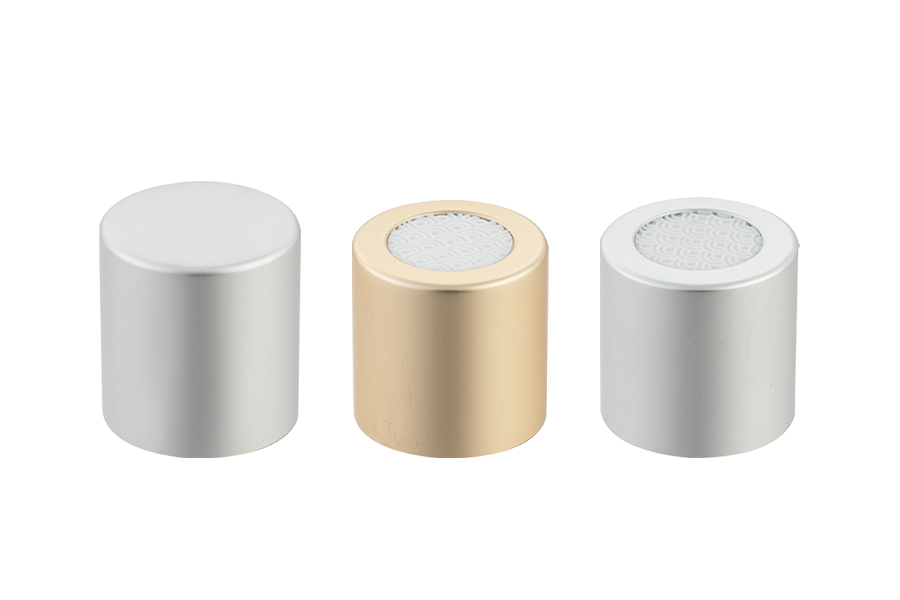

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material Aluminum-plastic Usage lotion bottle Custom Order: OEM o...

See Details -

Model Number Customized Material Aluminum-plastic Usage Cream bottle Custom Order: OEM or...

See Details

Copyright 2023 ? Zhejiang Xinbo Aluminium and Plastic Co., Ltd. All Rights Reserved. Aluminum Plastic Cosmetic Packaging Manufacturer

简体中文

简体中文 English

English