As a material for aluminum labels, mirror aluminum has shown its incomparable unique advantages and distinctive characteristics in multiple dimensions. Through a precise polishing process, the surface of mirror aluminum has achieved mirror-like flatness, which can reflect the light of the surrounding environment and produce a dazzling glossy effect. This effect not only enhances the visual appeal of the product, but also shows rich light and shadow changes under different light conditions, adding a unique charm to the product.

With the help of advanced printing technologies such as screen printing, thermal transfer or laser printing, mirror aluminum labels can present rich colors and complex pattern designs. Whether it is monochrome printing or full-color images, it can achieve delicate and clear printing effects to meet customers' customized needs for personalized colors and patterns.

Mirror aluminum has a low density but high strength, which enables it to reduce the overall weight while ensuring the quality of the label, making it easy to carry and install. In addition, its good toughness also ensures the durability of the label during transportation and use. The specially treated mirror aluminum surface forms a dense oxide film, which can effectively resist the erosion of harsh environments such as moisture, acidity, alkalinity, etc., prevent the label from rusting, fading or deformation, thereby extending the service life. Mirror aluminum has excellent thermal conductivity and electrical conductivity, which makes it perform well in application scenarios that require heat dissipation or conduction. For example, in LED lamps, mirror aluminum labels can be used as reflectors to improve the utilization rate of light; in electronic products, they can be used as heat sinks to help the equipment dissipate heat.

Mirror aluminum has good ductility and plasticity, and can be easily formed through shearing, stamping, cutting and other processing methods to meet customers' various customized requirements for label shape, size and thickness. With the help of advanced laser cutting, CNC stamping and other processing equipment and technologies, mirror aluminum labels can be made with high precision, ensuring that the details of the label's pattern, text, edges and other details are clear and accurate, meeting customers' high quality requirements.

Mirror aluminum labels are widely used in lighting fixtures, solar thermal collectors, interior building decoration, exterior wall decoration, household appliances, electronic products, furniture and kitchen, and automotive interior and exterior decoration due to their unique appearance and excellent physical properties. In these fields, mirror aluminum labels not only play a decorative and identification role, but also enhance the overall value and market competitiveness of the product. The high-end appearance and high-quality craftsmanship of mirror aluminum labels make them an excellent carrier for corporate brand promotion. By customizing unique patterns, colors and texts, companies can integrate their brand concepts, corporate culture and product features into labels, thereby enhancing brand recognition and market influence.

As the material of aluminum labels, mirror aluminum has shown outstanding advantages and characteristics in appearance and decoration, physical properties, processing and customization, as well as application fields and brand promotion value. These advantages and characteristics make mirror aluminum labels have extensive competitiveness and application value in the market, and become a powerful tool for many companies and brands to improve product quality and market competitiveness.

Web Menu

Product Search

Exit Menu

Product Categories

As a material for aluminum labels, what unique advantages or characteristics does mirror aluminum have?

-

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion Bottle

Aluminum Label Aluminum-Plastic 24/410 Disc Top Cap, Press Top Cap, Disc Press Cap For Lotion BottleModel Number 24-410 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

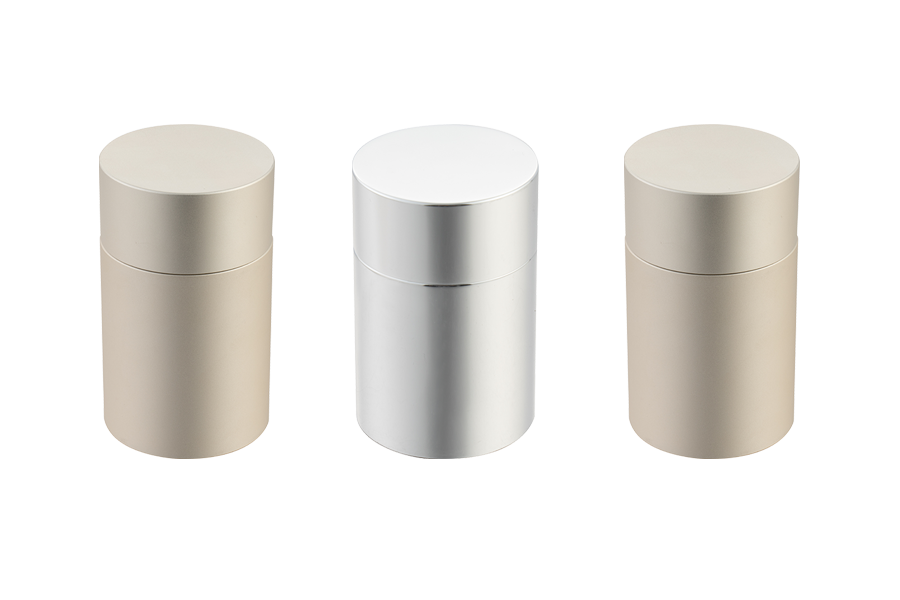

Model Number Customized Material Aluminum Usage tea caddy Custom Order: OEM or ODM Bran...

See Details -

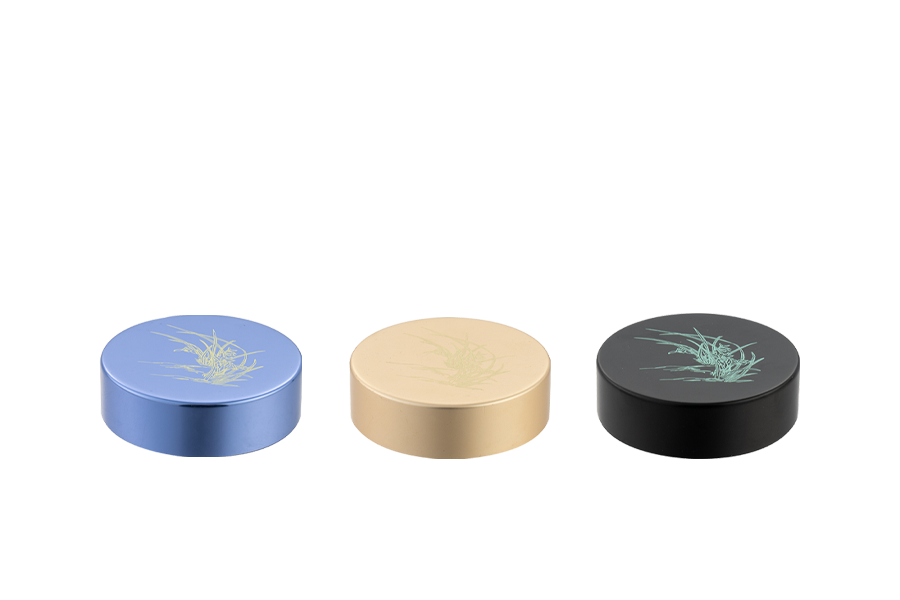

Model Number customized Material Aluminum Usage Bottles Custom Order: OEM or ODM Bran...

See Details -

Model Number 28-415 Material Aluminum-plastic Usage lotion jar Custom Order: OEM or ODM ...

See Details -

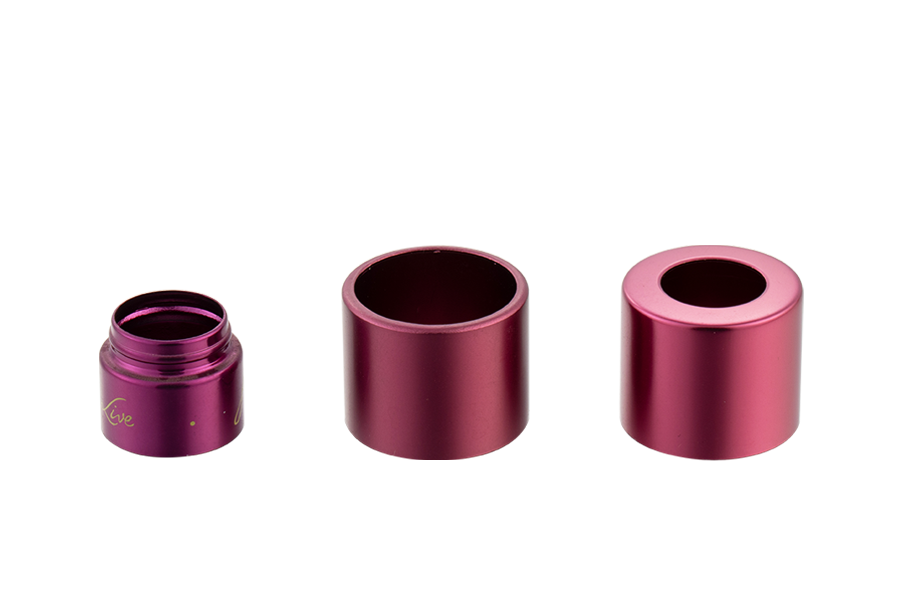

Model Number 89-400-26 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

Model Number 89-400-16 Material Aluminum-plastic Usage cream jar Custom Order: OEM or ODM...

See Details -

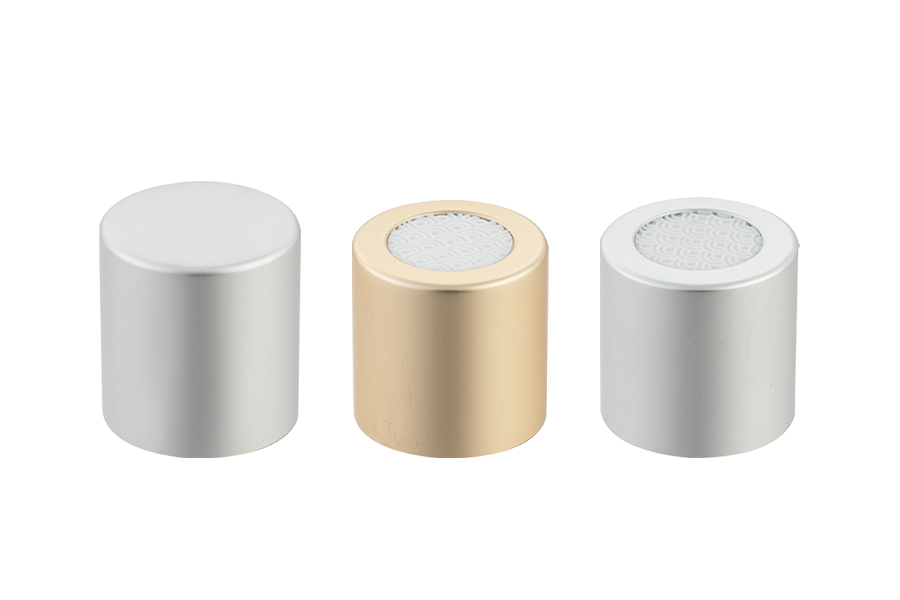

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number customized Material Aluminum-plastic Usage perfume jar Custom Order: OEM or...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material plastic Usage fragrance jar Custom Order: OEM or ODM B...

See Details -

Model Number Customized Material Aluminum-plastic Usage lotion bottle Custom Order: OEM o...

See Details -

Model Number Customized Material Aluminum-plastic Usage Cream bottle Custom Order: OEM or...

See Details

Copyright 2023 ? Zhejiang Xinbo Aluminium and Plastic Co., Ltd. All Rights Reserved. Aluminum Plastic Cosmetic Packaging Manufacturer

简体中文

简体中文 English

English